See the savings of a DURMETAL® Kit in your industry!

Ask us for a quote for your DURMETAL® Repair Kit!

See the savings of a DURMETAL® Kit in your industry! Ask us for a quote for your DURMETAL® Repair Kit!

|

||

| Live Repair (Video) | ||

| Click here to CONTACT us and register for a Preferred Customer Discount |

Only a few examples of our collection of customer testimonials |

|

Chemical and Petrochemical Industries |

|

|

|

«We repaired a water jacket on a 100 horsepower ammonia

compressor using DURMETAL®. A hard freeze broke out a ten

inch chunk of the cast iron jacket very close to the main bearing.

We applied DURMETAL® in about two hours and avoided approx.

40 man-hours repairing the compressor.» |

«Repaired Butterfly valves successfully with DURMETAL®

Standard. Estimated savings $ 700.–.» |

|

|

«This is a DURMETAL® repair to a 11/2 copper elbow and

adjoining nipple. The problem was to stop a leak in a system

carrying an Ethylene Glycol solution at 40 lbs. pressure and

between 28° F and 30° F. We are pleased with the results and of

course the savings. A total break down could have run into

several thousands of dollars.» |

«Making this repair on a live steam line with DURMETAL® saved

us in several ways, for it would have taken a scheduled shut

down which are very costly.» |

|

|

«Repairs were made to one of our ammonia booster compressors (made of cast iron). The water cooling jacket sprung a leak. We could

not turn the compressor off for any great length of time as this compressor controlled our freezer temperatures.

We turned off the water to make the repair, but let the compressor run. We used DURMETAL® Standard. Two hours later we turned the

compressor back on. It did not leak.» |

|

|

|

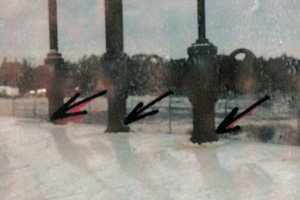

«Mainly, we have used your RAPID to patch gas leaks in our SO2 ducts and water leaks on our lead tanks. I have included before and

after photographs of two repairs. A RAPID patch on 30’’ SO2 gas duct and the other a STANDARD patch on a lead water reservoir for a

wet scrubber. These repairs would have eventually caused an outage of several hours which would have stopped production, and the

resulting heat-up would have used about $1200.– worth of natural gas. Thanks for a fine product that is well worth stocking!» |

|

|

|

«Had a application on a 30 000 gallon carbon steel tank that was

highly explosive from previously stored materials. It would have

been very expensive to clear and back weld to assure no further

leaks.

DURMETAL® went on as directed and should supply many years

of peace of mind. Since it worked so well on that tank we have

applied DURMETAL® to several leaking tanks containing

flammable material. Again, we did not have to spend a great deal

of money to safely clear them for welding.» |

«Leak on 10’’ flange: The pipe flange was wire drawn in seven

places. DURMETAL® Coldwelding was applied, covered with a

gasket, pressure applied with weight. Later the flange was filed

flat and connected back in line. It has been over 2 months now.

Working pressure is 420 psi at 400° F. The product in the line is

wet gas, 65% Hydrogen, 30% CO, 3% Nitrogen, 1% Methane,

1% Argon. This repair prevented us from a major shutdown.» |

|

|

«I was given a job to repair a 2 1/2’’ hole in the acid circulating tank in our Uranium mines plant. Thanks DURMETAL® I avoided approx. 2 hours of total plant shut down and considerable safety hazards.» |

|